Sondel Engineering & NewtonWorks: Advancing Sealing Technology with eSeal

At Sondel Engineering, we are committed to delivering cutting-edge engineering solutions, and our collaboration with NewtonWorks represents a significant step forward in sealing technology. By integrating eSeal, NewtonWorks’ advanced Finite Element Analysis (FEA) software, we bring a new level of precision, efficiency, and reliability to sealing solutions across industries.

Sondel Engineering is the official distributor for NewtonSuite eSeal for Europe. With our knowledge of rubber seal design, we understand that eSeal is a valuable tool saving brand owners, seal producers, and engineering companies time and costs. The time to market developments will be shorter by manufacturing the right seals the first time. Sharing knowledge is key in developing new products today; therefore, we’re happy to bring eSeal to our existing and new customers.

Naomichi Taketa, Account Manager at NewtonWorks Corporation

“Our collaboration with Sondel Engineering will help to deepen customer relationships and build continued trust with our European partners. As simulation specialists, NewtonWorks offers years of expertise in building world-class CAE software solutions. Although we’ve built ties with European partners previously, working with Sondel Engineering, as a group of localised experts, will further accelerate our European expansion of eSeal.”

Optimizing Sealing Performance with eSeal

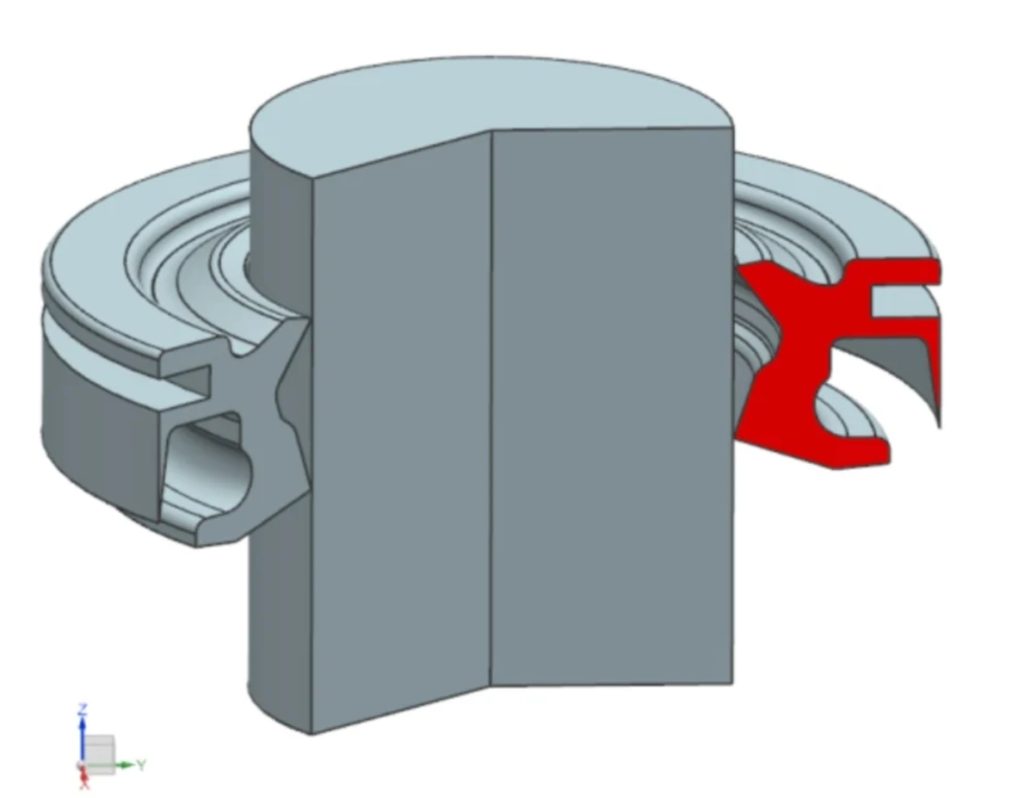

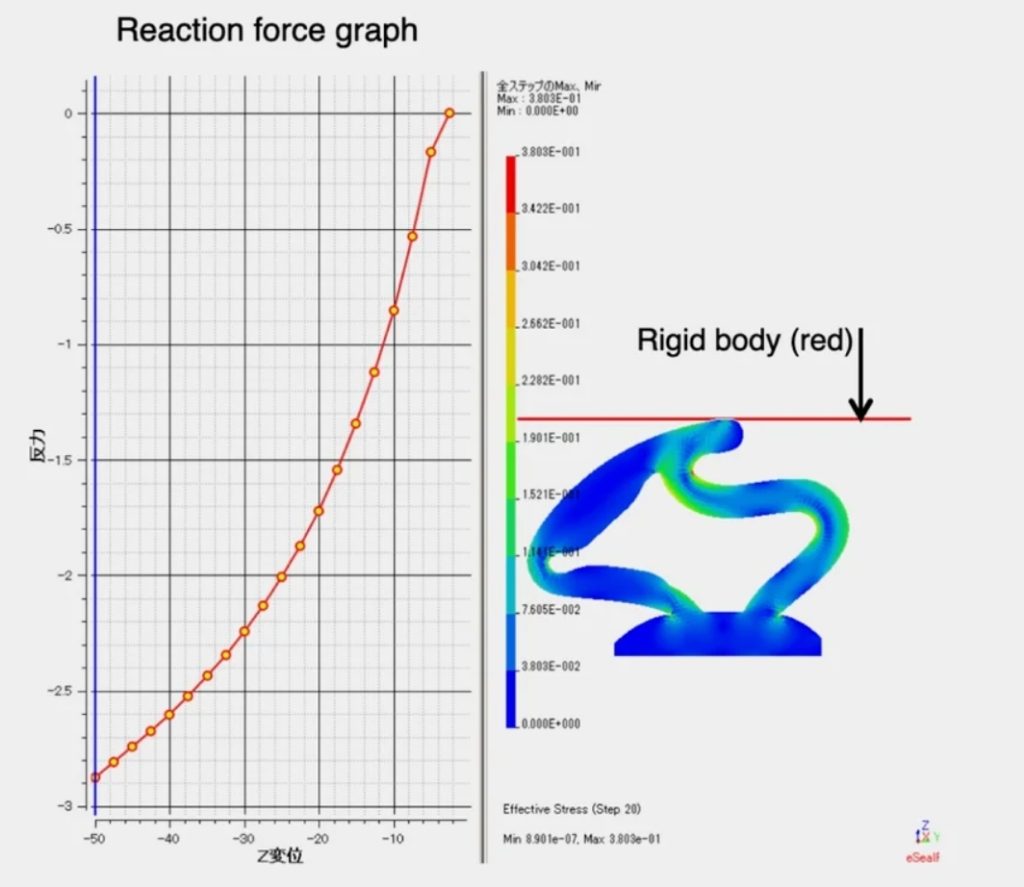

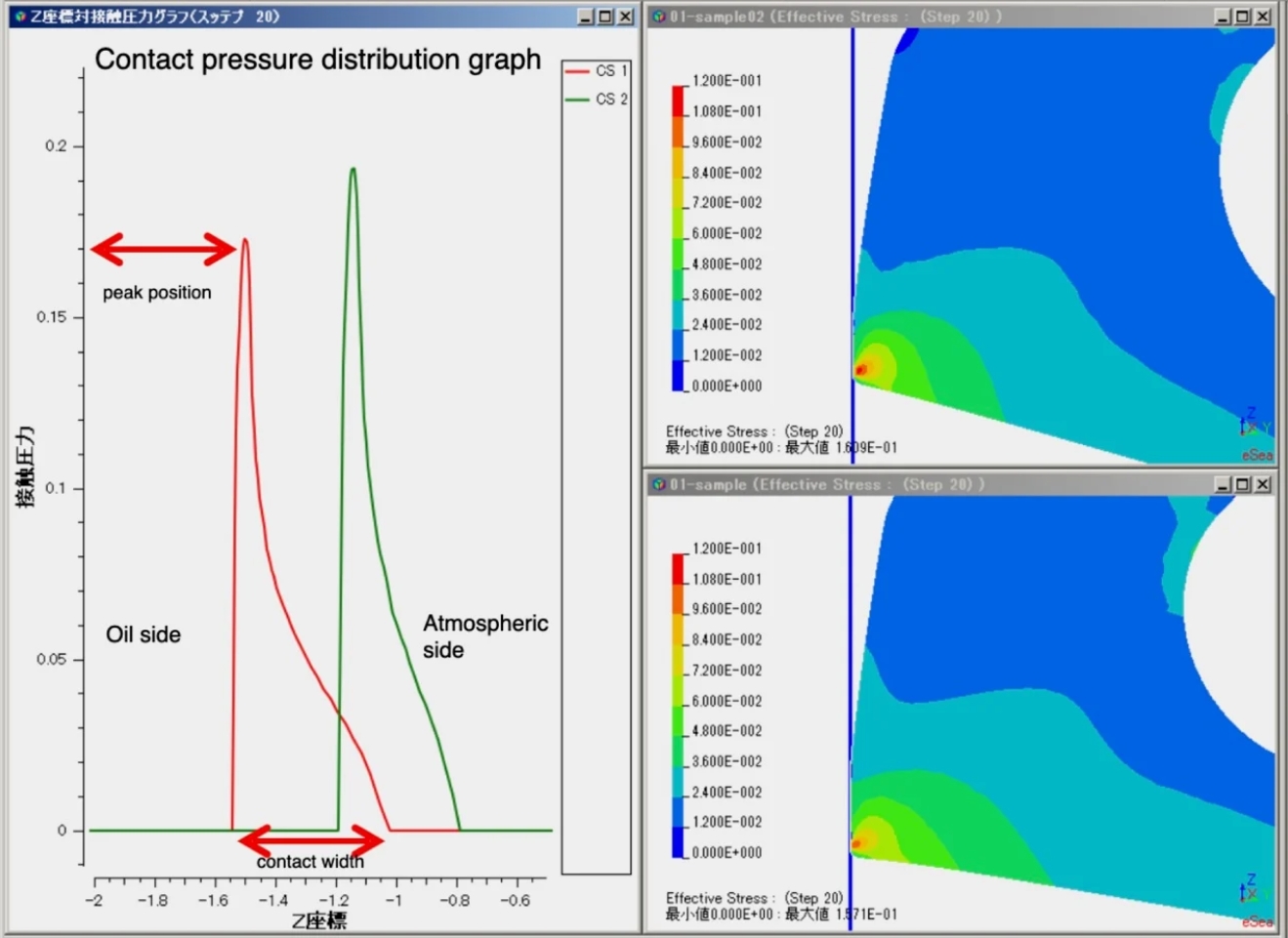

eSeal is a specialized FEA tool designed to analyze and optimize the performance of rubber seals, gaskets, and O-rings in real-world conditions. By simulating factors like pressure, temperature, and material behavior, we can predict seal performance before production, reducing costly iterations and improving product longevity.

How Our Collaboration Benefits You

🔹 Enhanced Design Accuracy – Predict potential failure points and optimize material selection before production.

🔹 Reduced Development Time – Accelerate the design process with precise simulations, cutting down on trial and error.

🔹 Improved Seal Reliability – Ensure superior sealing performance under extreme pressures and environmental conditions.

🔹 Cost & Material Efficiency – Minimize waste and unnecessary prototyping by refining designs virtually.

Industry Applications

The Sondel Engineering and NewtonWorks collaboration enhances sealing solutions in critical industries such as:

- Automotive & Aerospace – High-performance seals for engines, transmissions, and fuel systems.

- Industrial Machinery – Optimized gaskets and O-rings for hydraulic and pneumatic applications.

- Energy & Renewables – Durable sealing solutions for wind turbines, solar technology, and power generation.

- Medical & Food Processing – FDA-compliant rubber seals for sterile and hygienic environments.

Through this partnership, we are pushing the boundaries of sealing technology and FEA simulation, ensuring that our customers receive the most efficient, durable, and high-performing sealing solutions available.

Want to learn more about how eSeal can optimize your sealing applications? Contact us today to discuss your project.